Sx plastic machinery always symbolizes excellence. We have earned an excellent reputation for quality machines and thorough services. The key to our success comes from considerate services and quality assurance of our blow molding machines, coupled with efficient global marketing and competitive prices. Due to the support of our experienced personnel, innovative design, and quality-machine performance, our customers place complete trust and reliance on Sx.

Blow Moulding machine Process is a process of producing plastic hollow plastic products. This is different from PET Blow moulding machine process and is called Extrusion Blow moulding process. Blow moulding material grade is required for the same

Our Extrusion moulding Blow machine models offers both fast reliable production and energy efficiency (consumes low power)

Fully automatic yet have simple operations and are user friendly eliminating highly skilled man power requirements.

Plastic product making Blow machine built to handle wide range of product applications and offer value for money.

Our machine offers big advantage over space, power consumption, quality and productivity as compared to the complex large size machines available in the industry.

Extrusion moulding Blow Machines offered in models from 10 mls to 2000 mls capacities

Blow Machine models in Single / Double station

Blow Machines with optional Double Head producing 2 parisons

Mini Blow Models (100 & 200 ML)

Bottle Neck Cutting / Trimming Machine

We offer custom built machines to provide for any of your specific applications requirements.

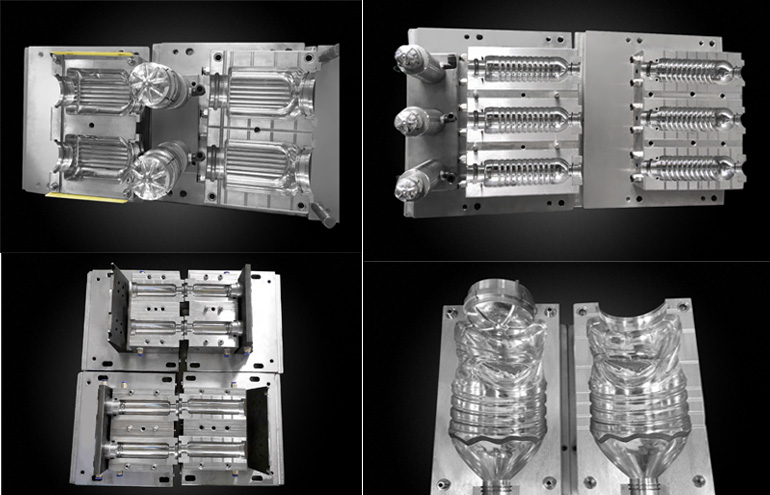

We are also plastic moulds and dies manufacturer in China and offer to develop your blow moulds and dies as per your design or samples.

We will offer you Blow moulds price as we received your plastic blow product drawings or sample

We also assist blow moulding Products development, training to your staff and other Technical inputs as required.