Extrusion blow molding machine is used to produce all kinds of the hollow plastic containers for foods, toys, beverages, medicines,chemical products, pesticides&detergents, water bottles,milk bottles,medical bottles,oil bottles,plastic balls,cosmetic bottles,lubricant bottles,plastic containers. The machines are low

investment, high efficiency, quick and safe operation, easy for trouble shooting, maintenance and other benefit.

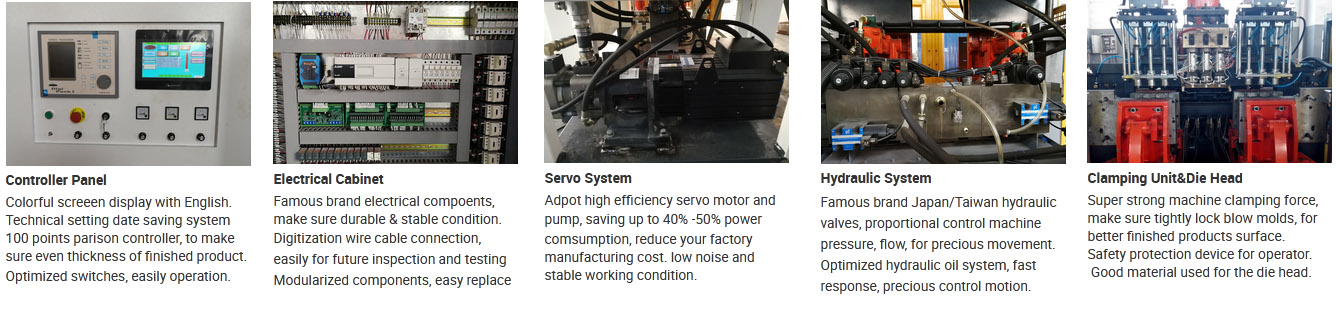

Machine component

We choose famous brand component for our machine. make sure the machine working stable and durable.Each machine would be tested over 72 hours automatically, to make sure every machine component are in good condition, would not bring any trouble to our customer.

Blow Mold

We have own mold department, we design drawing, manufacturing mold parts, assembly together, testing molds on our machines, make sure running goods before shipment.

We choose quality mold material, such as P20, Aluminum, BeCu, for better finished product.

Mold design with optimized cooling system, help to reduce cooling time, increase production speed.

Mold with deflashing, automatic running condition.

| Specification | Unit | SX-30L | SX-30L | |

| Suitable Material | PE PP HDPE PVC.. | PC | ||

| Max Product Volume | L | 30 | 30 | |

| Dry Cycle | Pcs/h | 650 | 650 | |

| Machine Size | m | 4.5*2.4*3.5 | 5.3*2.7*4.5 | |

| Machine Weight | Tons | 11.5 | 11.6 | |

| Clamping Force | Kn | 215 | 220 | |

| Platen Distance | mm | 400-900 | 400-900 | |

| Template Size(W*H) | mm | 760*660 | 760*660 | |

| Max Mold Size(W*H) | mm | 600*700 | 600*700 | |

| Screw Diameter | mm | 80 | 82 | |

| Screw L/D | L/D | 25 | 30 | |

| Screw Driver Power | Kw | 30 | 45 | |

| Screw Heating Power | Kw | 16 | 34 | |

| Screw Screw Heating Zone | Zone | 4 | 5 | |

| HDPE Output | Kg/h | 100 | 150(PC) | |

| Accumulator Capacity | L | 4.5 | 1.9 | |

| No of Die Heating Zone | Zone | 4 | 4 | |

| Powe of Heating Die | Kw | 12 | 8.7 | |

| Max Single Die Diameter | mm | 300 | 130 | |

| Total Power | Kw | 73 | 87.7 | |

| Oil Pump Motor | Kw | 15 | 45 | |

| Blowing Pressure | Mpa | 0.8 | 1.0 | |

| Air Consumption | M3/min | 0.8 | 0.8 | |

| Cooling Water Pressure | Mpa | 0.3 | 0.3 | |

| Water Consumption | L/min | 60 | 130 | |

| Average Power Consumption | Kw | 31.5 | 31.5 | |

Hydraulic multidie blow molding machine

This machine is mainly suitable for PP, PE material plastic products.lt could blow 50-2500 militer medicine bottle juice

bottle,chemical bottle,cosmetic bottle,ocean ball,welding rod packing box,automobile tripod box,bearing box etc.Optional function:

double layer, three layer, liquid view line, wall thickness controller, inner label, hydraulic pressure, 1-6 mold cavity number.