Full Automatic Extrusion Blow Moulding Machine is one-step method, one-time moulding, hydraulic, automatic incision and to flash device.It is suitable for producing PE,PP, AS and other hollow plastic containers and bottles in all shapes of different volume, This machine is widely used to produce the hollow plastic containers for foods, toys, beverages, medicines, chemical products, pesticides, detergents, etc. Fully automatic process with low investment, high efficiency, quick and safe operation, easy for trouble shooting, maintenance and other benefit. For its good quality and our perfect service, its your best choice to use it.

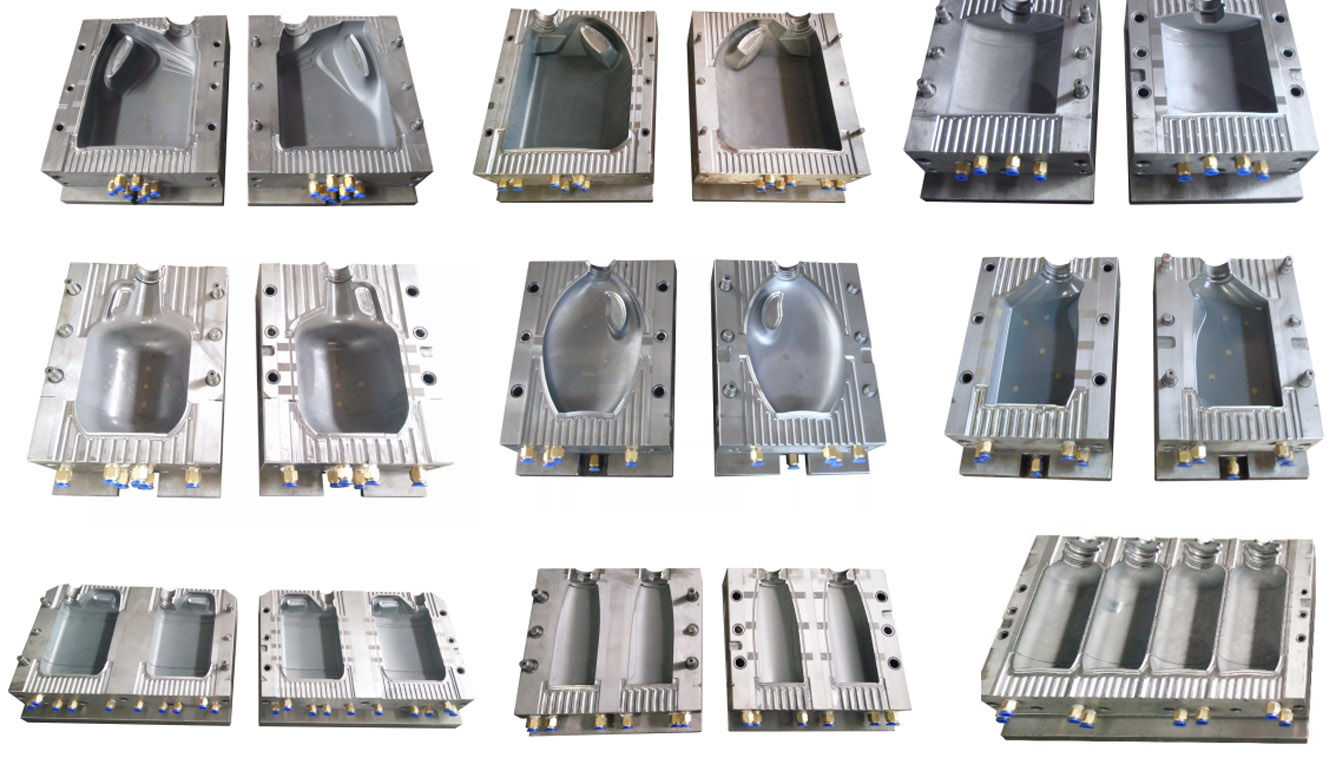

Blow Mold

We have own mold department, we design drawing, manufacturing mold parts, assembly together, testing molds on our machines, make sure running goods before shipment.

We choose quality mold material, such as P20, Aluminum, BeCu, for better finished product.

Mold design with optimized cooling system, help to reduce cooling time, increase production speed.

Mold with deflashing, automatic running condition.

| Model | Unit | SX-B65 | |||

| Screw Diameter | mm | 65 | |||

| Extrusion Capacity PP,PE | kg/h | 90 | |||

| PC.PVC | 60 | ||||

| Dry Cycle | s | 10 | |||

| Screw Diameter | L/D | 27:1 | |||

| Mold Center Distance | mm | ||||

| Screw Rotating Speed | R/min | 10-75 | |||

| Mold Stroke | mm | 220-520 | |||

| Max. Mold Dimension(W×H) | mm | 350×380 | |||

| Length of Mold Capacity | mm | 100-350 | |||

| Drive Motor Capacity | kw | 22 | |||

| A | 44.7 | ||||

| Hydraulic Pump Capacity | kw | 11 | |||

| A | 22 | ||||

| Number of Heaters | 6 | ||||

| Heating Capacity | kw | 7.2 | |||

| A | 32.7 | ||||

| Clamping Force | T | 7 | |||

| Weight of Product | G | 40-500 | |||

| Max. Product Capacity | ML(Φ) | 5000 | |||

| Total Electric Power | kw | 29.7 | |||

| Weight | kg | 6150 | |||

| Dimension | L×W×H(mm) | 3630×2265×2280 | |||

| Transfer Displacement Stroke | mm | 420 | |||

| Air Pressure | kg/cm | 6-8 | |||

| Air Consumption | m³/min | 0.5 | |||

| Cooling Water Pressure | Mpa | 0.3 | |||

| Cooling Water Consumption | L/min | 50 | |||

SHENGXIN company was founded in 2010, the company is located in Huangyan, Taizhou, Zhejiang Province, the hometown of mould in China. The company's main R & D, manufacturing two-step blow molding machine, hollow extrusion blow molding machine, preform mold, blow mold.

It is mainly used in the production of mineral water bottles, edible oil bottles, food packaging bottles, daily chemical bottles, agricultural medicine bottles, and many other plastic container packaging fields. Provide a variety of targeted models of production equipment, and provide a sound technical solutions.

The company has a number of imported CNC machining centers and high-quality design, production, after-sales team, which has laid a solid foundation for product quality, performance and details. With solid workmanship and excellent performance, the products are exported to America, the Middle East, Southeast Asia, Central Asia, Africa, Europe and other countries and regions, and are well received by the majority of users.

The company adheres to the advanced design concept, pragmatic and innovative spirit, and constantly improve the production process, strengthen the detection means, committed to providing users with stable, efficient, energy-saving and environmental protection equipment. And to provide users with efficient after-sales service and product solutions.

Our tenet: SHENGXIN machinery is worthy of your trust partner, hand in hand to create a better tomorrow.